An in-depth study with your peers has revealed four pervasive challenges that extend across the industry, that may be impacting your business.

Asset Unsure

How many doors or levelers are there in your fleet?

What are the makes, models, or health of the assets?

Operational Efficiency

How often do your assets experience downtime?

What is the dollar impact to revenue from downtime?

Asset Spending

How much is spent annually on asset maintenance?

How much is spent by partner and how do you correlate it to service levels or assets performance?

Anomalous Events

Have doors required maintenance due to an unknown incident?

Has equipment ever failed right before closing time? Result in an emergency?

Why you should care

The Problem

The Impact

The Problem

95%

Asset Unsure

Lack Asset Awareness

Counts, models, operational State

The Impact

- Capital replacement plans done by committee and top down, lacking analytics

- Decision-making process blind, impacting facility strategy and creating potential reactive hazards

The Problem

17.7

days

Operational Efficiency + Asset Spending

Average Downtime To Repair

From initial assessment by technician

The Impact

- Unplanned equipment downtime impacts overall business operations

- Inoperable overhead doors and/or levelers can cost thousands per day in revenue

The Problem

8%

Anomalous events

Service calls are e-calls

To repair or make safe an asset

The Impact

- Operating blindly by means of perceived asset health necessitates accepting emergency call costs

- Increases forecasted and realized OPEX allocation for overhead doors and levelers

How we can help

The Problem

95%

Asset Unsure

Lack Asset Awareness

Counts, models, operational State

The Impact

- Capital replacement plans done by committee and top down, lacking analytics

- Decision-making process blind, impacting facility strategy and creating potential reactive hazards

The Problem

17.7

days

Operational Efficiency + Asset Spending

Average Downtime To Repair

From initial assessment by technician

The Impact

- Unplanned equipment downtime impacts overall business operations

- Inoperable overhead doors and/or levelers can cost thousands per day in revenue

The Problem

8%

Anomalous events

Service calls are e-calls

To repair or make safe an asset

The Impact

- Operating blindly by means of perceived asset health necessitates accepting emergency call costs

- Increases forecasted and realized OPEX allocation for overhead doors and levelers

Introducing the fortify platform

Facility Survey App

Solution for:

Asset Unsure

Collecting, curating and surfacing asset data by facility

Asset data including make, model, componentry, and peripheral insights

Industry-first FORTIFY health assessment grade

Introducing the fortify platform

+

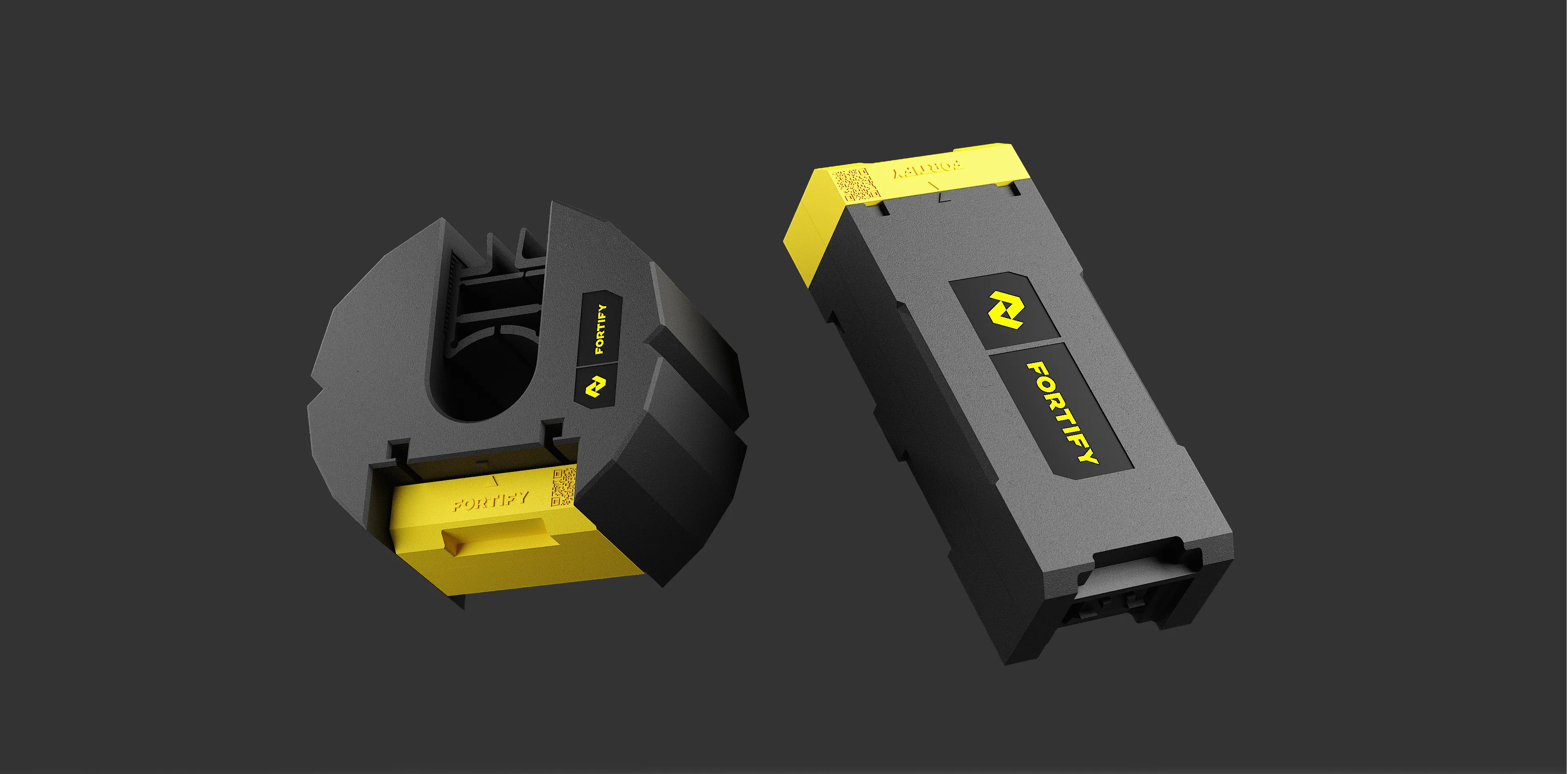

Facility Sensors

Solution for:

Operational Efficiency

Anomalous Events

Sensors collect + monitor critical data in near-real time

- Lifetime cycle count/Cycles since PM

- Temperature/humidity

- Door/Leveler State

- Time-In-State

Identify distinct operational patterns

Powers the HUD

Affixes easily to asset

Introducing the fortify platform

Command Center App

Solution for:

Asset Spending

Single ‘pane of glass’ curating actionable insights

Persona-based data lens providing flexibility to view single facility or multiple based on role-access permission

Access from anywhere, anytime to monitor, analyze or action

Collaborate within the application or share directly from the HUD

Join us for the next horizon of innovation in loading dock equipment and be the next partner in 2026 as we deploy to more than 30,000 assets.